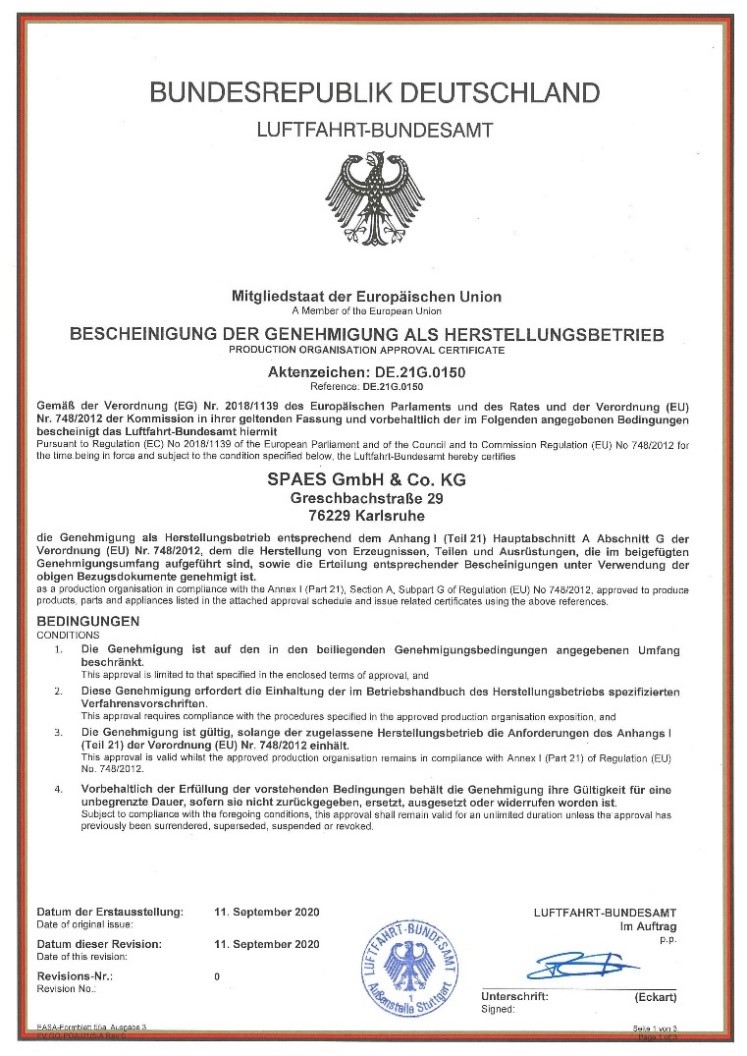

SPAES receives the approval for the Part 21G Production Organisation to manufacture and produce components according to aviation standards (Form 1).

Due to the increasing demand of customers for the procurement and production of components according to aviation standards, SPAES decided to establish an EASA Part 21G production organisation.

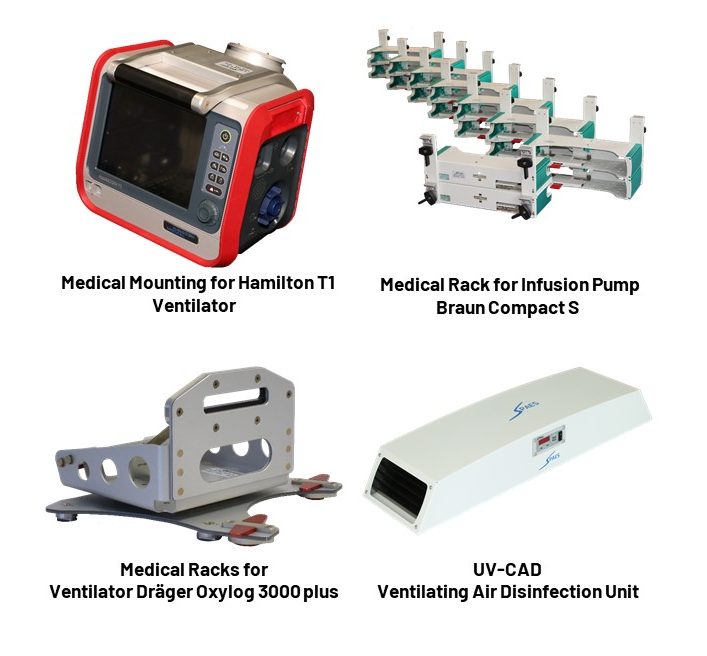

For certification of the Part 21G organisation it was accompanied by four reference projects, including a mounting bracket for the Hamilton T1 ventilator for the Airbus H145 helicopter.

“With the existing Part 21J design organization and the new Part 21G Production Organization approval, we can offer our customers a complete package and thus cover the value chain from the idea to the production of a product,” says Nikolas Kares, Head of Production Organization at SPAES.

As of now, SPAES not only manufactures their own products but also issues them with a certificate of conformity (EASA Form 1). This certificate of release proves that the product was manufactured in accordance with the approved design data and is therefore suitable for installation in aircraft.

“This is a positive and logical development for SPAES. In order to reduce costs and effort, the offer of the design, approval and manufacturing of products and components from one source is becoming more and more important for our customers” says Joachim Schanz, founder and managing director of SPAES

The focus of the Part 21G Production Organisation is currently in the area of metal processing and assembly, composite manufacturing and wire harness production and will be gradually expanded to meet customer specific requirements.