Manufacturing

With proper aircraft equipment, any mission can be accomplished successfully. Due to the small space in the cockpit and passenger compartment, the equipment must be optimally coordinated and designed. Even after a long period of use, the equipment and the products will continue to meet your requirements. Good quality manufacturing is the foundation of any medical and mission equipment.

SPAES, as a certified Part 21G Production Organization, is able to manufacture, certify and deliver the equipment, components and installation kits for airplanes and helicopters and approves it with EASA Form 1 specifications.

For the approval of our customers‘ own components and assemblies, we have been offering the production and final assembly of simple to highly complex parts and systems for years.

Our large supplier network in the aerospace industry enables us to use the best materials and parts for your products.

Make no compromises and come to SPAES.

Our portfolio

- Cable production

- Laser printing of all common aviation cables

- Assembly of printed circuit boards

- Wiring

- Glass fibre

- Carbon fibre

- Aramid fibre

- Honeycomb

- Turning and milling

- Sheet Metal working

- Painting

- Anodizing

- Chromating

- Passivation

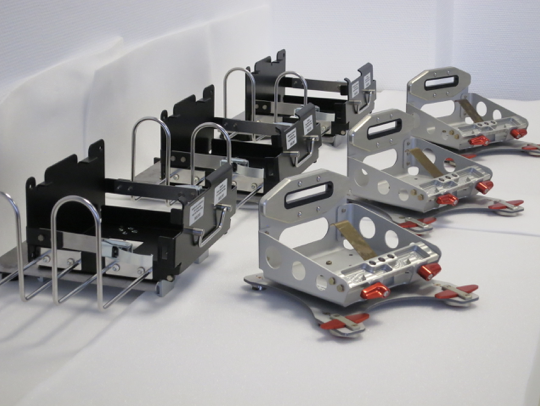

- Assembly of components and devices

- Single / serial production

- Prototype manufacturing

- Wiring

- Renewal of Seat Covers and Carpets

- Manufacture of trim

- Renewal of leather covers

- Built-in cabinets and storage compartments

- Device Holders

- Entertainment Systems

- System integration in Aircraft and Helicopters

- Cockpit modification and conversions

- Installation support

- Prototyping

UV Laser Wire & Cable Marking LaserLec MRO 200 B

SPAES offers you the production of single cables and complete wire harness, which can be produced in combination with the installation of avionic systems or as single order. The cables are individually adapted and printed according to aviation standards using UV laser technology to meet your requirements.

- Processing of cable lengths from 15 cm to 999 m

- High flexibility in the creation and selection of font size

- Secure, permanent and high-contrast identification marking

- For cable types, such as single or multi-core jacketed, twisted cables with PTFE (Teflon®), FEP (Tef-lon®), ETFE (Tefzel®), XL-ETFE (Tefzel®),

- Unchangeable marking

- Precise, non-detachable and non-aggressive marking of cylindrical and twisted shielded cables from AWG 6 to 26 (6,30mm bis 0,75mm)

The MRO 200 marking machine complies with international aviation standards such as e.g. SAE ARP5607, BAC 5152 (BOEING), AIPS (AIRBUS)

The LaserLec MRO200 B is also qualified by the major aircraft manufacturers and is used in civil and military programs worldwide, including e.g.:

- AIRBUS

- AGUSTA-WESTLAND

- BELL HELICOPTER

- BOMBARDIER / LEARJET

- DASSAULT

- EMBRAER

- EUROCOPTER

- SIKORSKY

If you need further information regarding cable printing please do not hesitate to contact us.