SPAES extends its portfolio and is now offering Printed Circuit Board (PCB) Assembly in its own EASA Part 21G Production Organization

Due to the shutdown of the 2G network, a telephone modem for a helicopter was manufactured for a customer and the data transfer system was exchanged from 2G to 4G in an Airbus H125.

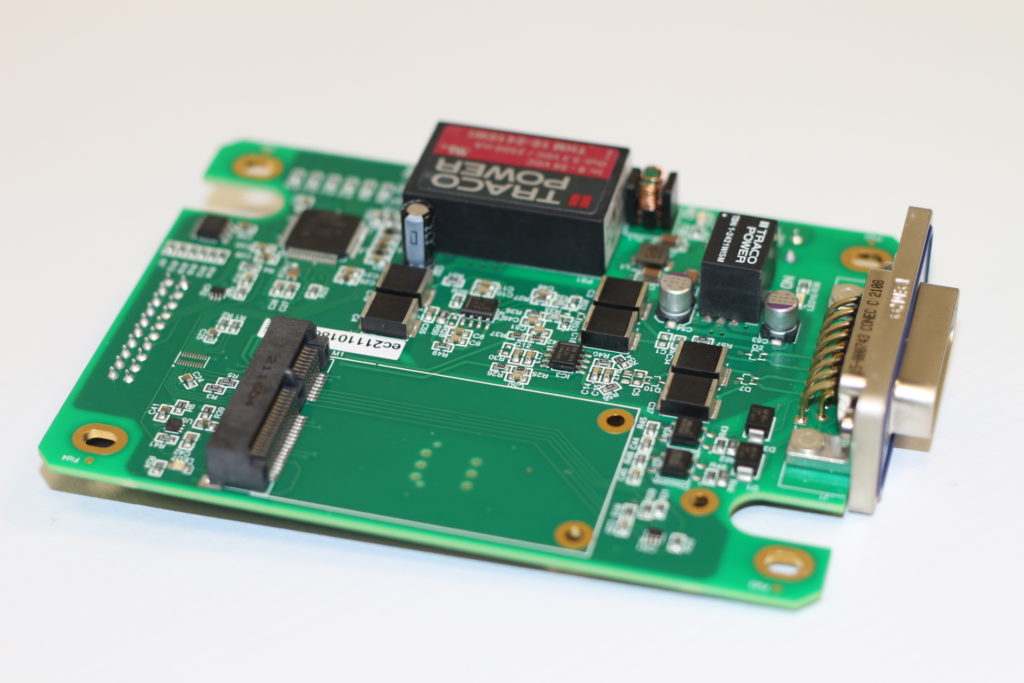

The telephone modem is used in the helicopter to communicate with on-the-ground units. SPAES offered the complete package from start to finish – from PCB assembly to the installation of the software on the device up to subsequent test report according to the specifications of the EASA Part 21J Design Organization.

Two basic methods were used for mounting the printed circuit boards: Surface Mount Device (SMD) and Through Hole Technology (THT). Connections of THT components are inserted through holes on the PCB and soldered from below. SMD components do not require holes but are mounted or placed directly onto the surface of the Printed Circuit Board.

The Installation documents and the Minor Change came from the customer and SPAES offered the PCB assembly in its own EASA Part 21G Production Organization and issued an EASA Form 1 Release Certificate.

From simple single sided PCB to complex multilayer PCB – a whole range of services is provided and tailored to customer requirements.